1. Overview of Fiber Optic Connectors

A fiber optic connector is a device used to achieve detachable (movable) connections between optical fibers. It precisely aligns the end faces of two fibers to ensure maximum coupling of light energy from the transmitting fiber into the receiving fiber. As a critical component in optical communication systems, fiber optic connectors play an indispensable role in ensuring efficient, low-loss transmission of optical signals.

2. Main Structure of Fiber Optic Connectors

A typical fiber optic connector consists of the following core components:

- Ferrule: Usually a precision ceramic (zirconia) or stainless steel cylinder with a micro-hole to secure the fiber.

- Connector housing: Provides mechanical protection and connection mechanisms.

- Coupling mechanism: Ensures alignment accuracy during connection (e.g., bayonet, push-pull types).

- Strain relief device: Protects the fiber from mechanical stress.

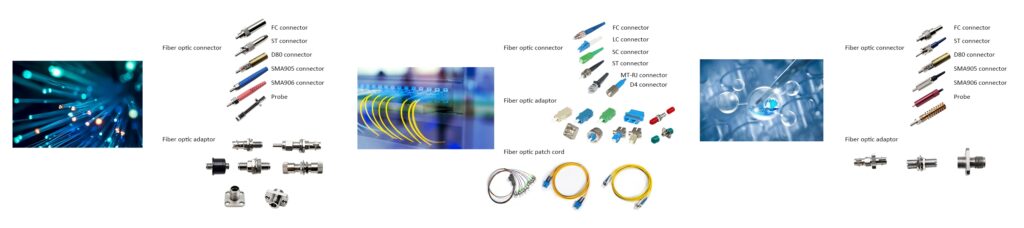

3. Common Types of Fiber Optic Connectors

1. Classification by Interface Type

- FC connector: Uses a metal threaded coupling mechanism, widely used in early applications and now mostly in test instruments.

- SC connector: Square plastic housing with a push-pull mechanism, commonly used in data centers.

- LC connector: Compact design, half the size of SC, preferred for high-density applications.

- ST connector: Bayonet-style locking mechanism, often used in LAN environments.

- MTP/MPO connector: Multi-fiber connector (typically 12/24 fibers), used in high-speed data centers.

2. Classification by Polishing Type

- PC (Physical Contact): Slightly curved end-face polishing.

- UPC (Ultra Physical Contact): Ultra-precision polishing, providing higher return loss.

- APC (Angled Physical Contact): 8-degree angled polishing, offering the best reflection performance.

3. Classification by Fiber Mode

- Single-mode fiber connectors: For 9/125μm single-mode fibers.

- Multimode fiber connectors: For 50/125μm or 62.5/125μm multimode fibers.

4. Key Performance Metrics of Fiber Optic Connectors

- Insertion Loss: Typically <0.3dB.

- Return Loss: UPC >50dB, APC >60dB.

- Repeatability: Performance stability after multiple insertions and removals.

- Interchangeability: Compatibility between connectors of the same type.

- Temperature Performance: Stability across -40℃ to +70℃.

- Durability: Usually exceeds 1,000 mating cycles.

5. Application Fields of Fiber Optic Connectors

1. Telecommunications

- Long-haul backbone transmission systems

- Fiber-to-the-Home (FTTH) access networks

- Mobile base station interconnections

2. Data Centers

- Server-to-switch connections

- Storage Area Networks (SAN)

- High-speed interconnects (40G/100G/400G)

3. Cable TV (CATV)

- Hybrid Fiber-Coaxial (HFC) networks

- Video signal distribution systems

4. Industrial Applications

- Industrial automation control systems

- Oil and gas monitoring

- Power system communications

5. Military & Aerospace

- Airborne communication systems

- Naval fiber optic networks

- Field communication equipment

6. Medical Equipment

- Endoscopic imaging systems

- Laser therapy devices

- Medical sensing networks

6. Development Trends of Fiber Optic Connectors

- Miniaturization: Adoption of LC and CS connectors.

- High Density: Expansion of MTP/MPO in multi-fiber applications.

- Low Loss: Application of ultra-precision machining.

- Smart Connectors: Diagnostic-enabled intelligent connectors.

- Specialized Applications: High-temperature, radiation-resistant connectors for harsh environments.

With advancements in 5G, IoT, and AI, fiber optic connectors will continue evolving toward higher performance, smaller size, and lower cost, providing reliable optical interconnection solutions for global digital infrastructure.